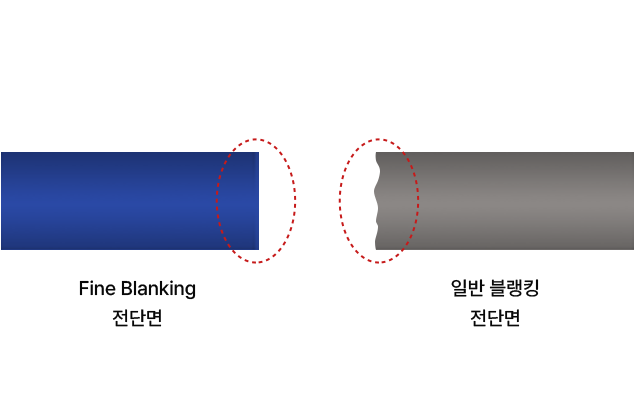

General blanking tends to have only some parts being sheared neatly while the other parts are rough.

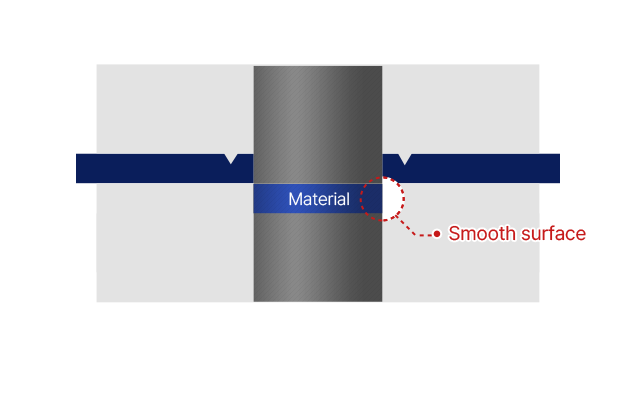

Fine blanking uses three different forces for shear and inhibits the fluidity of the material to minimize fractures on the shear surface.

More Precise Fine Blanking with Three Different Forces

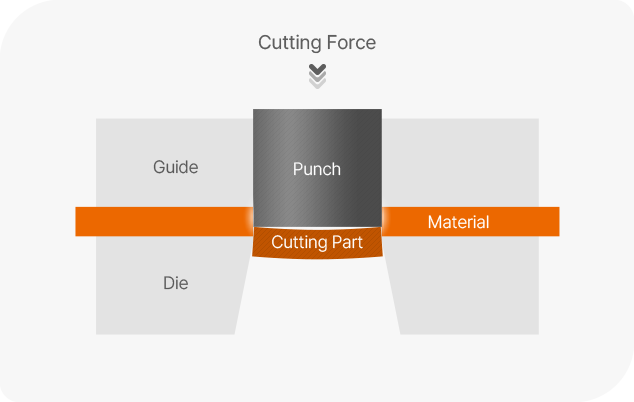

The general blanking technique that cuts materials using a single force in the production process has limitations on the evenness of the shear surface due to fractures.

Fine blanking uses three different forces and can deliver a clean shear surface and precise outcomes.

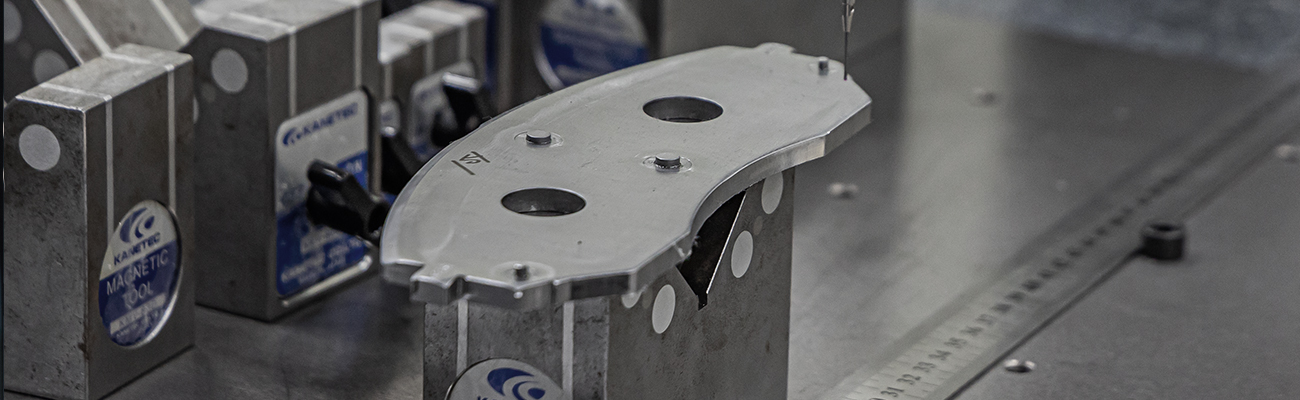

General blanking

Fine blanking

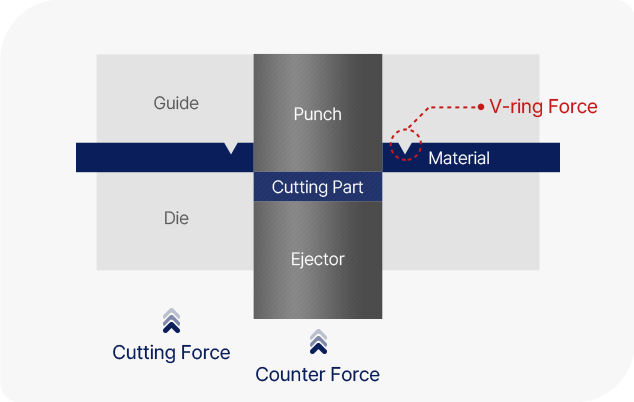

Detailed Process of Fine Blanking

It inhibits fluidity and minimizes fractures on the shear surface using three different forces, V-ring, counter, and cutting, for shearing.

Step 01.

Fixing material with clamping force and V-ring force

Step 02.

Cutting with Cutting Force

Smooth surface

Comparing sucfaces

Strengths of Fine Blanking

Suitable for mass production of high-precision parts

- Minimizes fractured surfaces

- Smooth surface

- Minimizes post-processing

Multiple stages of processing with one equipment

Reduces cost with less processes

Create income of more than about 100,000 components a year

Bigger financial gain than investments